Custom Solutions

When you are looking for a custom transformer or inductor you want the very best. Our team is not just qualified, we are one of the most capable transformer design teams in North America, period.

Customization

We have more than 500 successful designs to our credit, and our transformers and inductors are presently used in medical devices, aircraft, communications equipment, semiconductor processing equipment and test and measurement devices. We will carefully consider ALL of your design objectives.

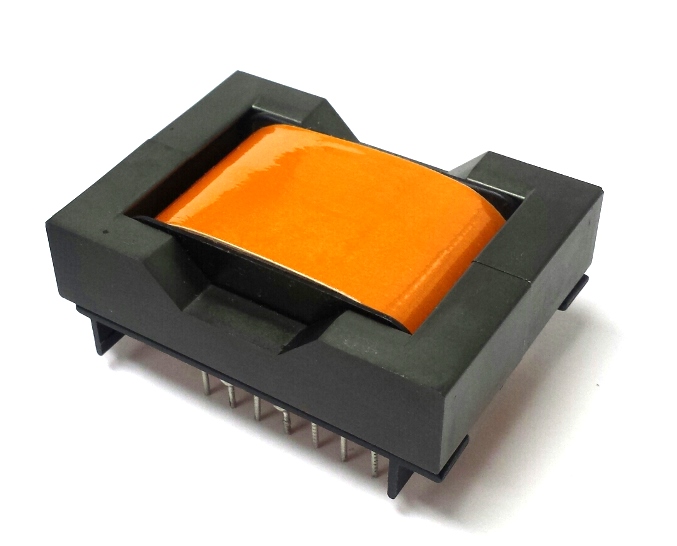

Custom Transformer Design

It should not be surprising that when it comes to transformers, we are an industry leader. We know a lot about core materials and types of windings. As an added bonus, with 3D modeling capability we can also build a transformer from a totally clean sheet of paper without having to choose from off the shelf cores and bobbins. This is a pretty powerful combination of capabilities and it yields some remarkable results.

Flyback, impedance matching, current sense, push-pull, linear, forward or half bridge: we have seen it all. Whether you are at 1 Watt of power or 100 kW we have you covered. We will design a transformer that will meet 100% of your requirements at the lowest possible cost.

Custom Inductor Design

Our team has been pretty disappointed with the lack of improvement in the standard inductors we see on the web every day. To be honest, they just don’t measure up to where modern power supplies are headed. We decided to do something about it. We have done a lot of research on inductor technology and we have patented a number of ways to reduce high frequency winding losses. We’ve also started designing our own cores and bobbins to make sure that we are offering the very best

Your inductor’s custom design begins with a comprehensive exploration of your needs and ends with the best core material and conductors available.

Custom Common Mode Choke Designs

A common mode choke is pretty simple. You want a high level of impedance over a reasonably large bandwidth in the smallest possible package at the lowest price. And you want to meet safety agency requirements for isolation. We have been there, over and over again. The story here is much the same. Using the right core, with the right winding, in a package that meets all your requirements will yield the lowest possible lifetime requirements. We have the team in place to realize this for you.

Bonded Coils

WCM has extensive expertise in manufacturing bonded coils. This cylindrical design is an inductor used in a test and measurement device. It has 7 mH of inductance and can handle up to 1 amp of current in a package only 1.6” in diameter and 0.65” in height. With no core, inductance is highly stable with temperature and excitation. WCM can manufacture bonded coils up to 12” in diameter and length, and as small as 0.2” in diameter. We are process capable with wire gauges from 40 awg to 16 awg.

Ask a Question

Ask a Question